Master Your Boat's Safety: The Complete Visual Guide to Dock Line Size Charts

Transform Complex Sizing Data into Clear, Actionable Safety Decisions

As someone who's spent countless hours at marinas watching boats strain against inadequate lines, I've learned that choosing the right dock lines isn't just about following a simple chart—it's about understanding the complete picture of your vessel's mooring needs. Let me guide you through everything I've discovered about selecting, sizing, and maintaining the perfect dock lines for your boat.

Why Precision Matters in Maritime Mooring

I've witnessed firsthand the consequences of improper dock line selection—from minor boat damage to complete vessel loss during storms. The truth is, selecting the right dock lines is one of the most critical safety decisions you'll make as a boat owner.

Many boaters fall into the trap of thinking bigger is always better, or that any rope will do. I've learned through experience that this misconception can lead to equipment failure, excessive wear on cleats, and dangerous situations during adverse weather. The key is understanding that dock line selection involves multiple variables working together.

Critical Factors Beyond Boat Length:

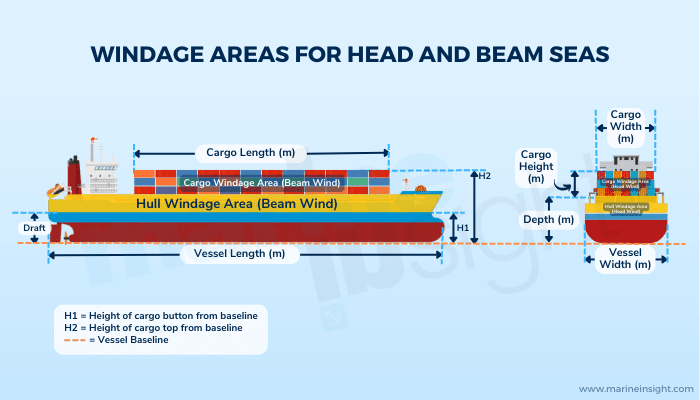

- Vessel displacement and windage profile

- Local tidal ranges and current patterns

- Dock configuration and hardware compatibility

- Seasonal weather patterns and storm frequency

When I discovered how PageOn.ai could transform complex sizing tables into interactive visual guides, it revolutionized how I help fellow boaters understand these relationships. By using data visualization charts, we can instantly see how different factors influence our dock line choices.

Decoding the Essential Components of Dock Line Size Charts

Understanding a dock line size chart requires more than just matching your boat length to a rope diameter. I've developed a comprehensive approach that considers all the critical factors that influence line performance and safety.

Key Components Relationship

flowchart TD

A[Boat Specifications] --> B[Length Overall]

A --> C[Displacement/Weight]

A --> D[Windage Profile]

B --> E[Line Diameter]

C --> E

D --> F[Additional Safety Margin]

E --> G[Tensile Strength]

F --> G

G --> H[Working Load Limit]

H --> I[Final Line Selection]

Tensile Strength vs. Working Load

I always explain to new boaters that tensile strength represents the breaking point, while working load limit (typically 15-20% of tensile strength) is what we actually design around for safety.

Displacement Considerations

A heavy displacement trawler requires stronger lines than a lightweight speedboat of the same length—something I learned after seeing a 35-foot trawler snap lines sized for its length alone.

By leveraging PageOn.ai's AI Blocks, I can create customized visual representations that show exactly how these factors interact for specific vessel types, making complex engineering data accessible to every boater.

The Standard Dock Line Size Chart: Your Visual Reference Guide

After years of helping boaters select proper dock lines, I've refined the standard sizing chart into a comprehensive visual guide that accounts for real-world conditions.

Dock Line Diameter by Boat Length

Pro Tip from Experience:

I always recommend going up one size if your boat has high windage, is kept in an exposed location, or if you're in an area with significant tidal ranges. The minimal extra cost provides substantial peace of mind.

Understanding Line Length Requirements

Bow and Stern Lines

Length: 1/2 to 2/3 of boat length

I've found that 2/3 length provides optimal flexibility for various docking situations while maintaining control.

Spring Lines

Length: Equal to boat length

Spring lines are your primary defense against surge—never compromise on their length.

Creating interactive sizing tools with PageOn.ai's Deep Search capabilities has allowed me to develop boat-specific recommendations that consider individual vessel characteristics beyond simple length measurements.

Material Selection and Construction Types

Through years of testing different rope materials in various conditions, I've developed strong opinions about what works and what doesn't for dock lines. Let me share what I've learned about materials and construction methods.

Comparing Line Materials

| Material | Stretch | UV Resistance | Cost | Best Use |

|---|---|---|---|---|

| Nylon | Excellent (25-35%) | Good | Moderate | Primary dock lines |

| Polyester/Dacron | Low (12-15%) | Excellent | Higher | Spring lines in calm waters |

| Polypropylene | Moderate | Poor | Low | Temporary/emergency only |

Warning from Experience:

I've seen too many boats damaged because owners chose polypropylene to save money. It degrades rapidly in sunlight and can fail without warning. Never use it for primary dock lines.

Construction Methods Impact on Performance

Construction Type Performance Comparison

I've found that visualizing these material comparisons through PageOn.ai's Vibe Creation feature helps boaters immediately understand which construction method best suits their specific needs and budget constraints.

Environmental and Situational Factors Affecting Line Selection

One of the most valuable lessons I've learned is that dock line selection must account for your specific environment. What works perfectly in a protected marina may fail catastrophically in an exposed anchorage.

Weather and Water Conditions

Weather-Based Line Adjustment Guide

flowchart LR

A[Normal Conditions] --> B[Standard Size]

C[High Winds 25-35kt] --> D[+1 Size or Double Lines]

E[Storm 35kt+] --> F[+2 Sizes AND Double Lines]

G[Hurricane Prep] --> H[Maximum Available + Backup]

Tidal Range Considerations

In areas with 6+ foot tidal ranges, I always add 25% to standard line lengths and use floating dock systems when possible to reduce strain.

Current and Surge Protection

Strong currents require properly positioned spring lines. I've learned to cross them in an X-pattern for maximum surge control.

Dock System Compatibility

The type of dock system significantly impacts line selection and longevity. Here's what I've observed across different configurations:

Fixed Docks

Require longer lines with more stretch capacity. Chafe protection is critical at all contact points. I always use oversized chafe guards here.

Floating Docks

Allow shorter lines with less stretch needed. The dock moves with the boat, reducing strain significantly. My preferred system for line longevity.

Pilings Only

Most challenging for line wear. Requires careful positioning and constant adjustment. I recommend doubling chafe protection here.

By utilizing PageOn.ai's Agentic processes, I can create dynamic adjustment guides that automatically factor in local conditions, helping boaters make informed decisions based on their specific environment.

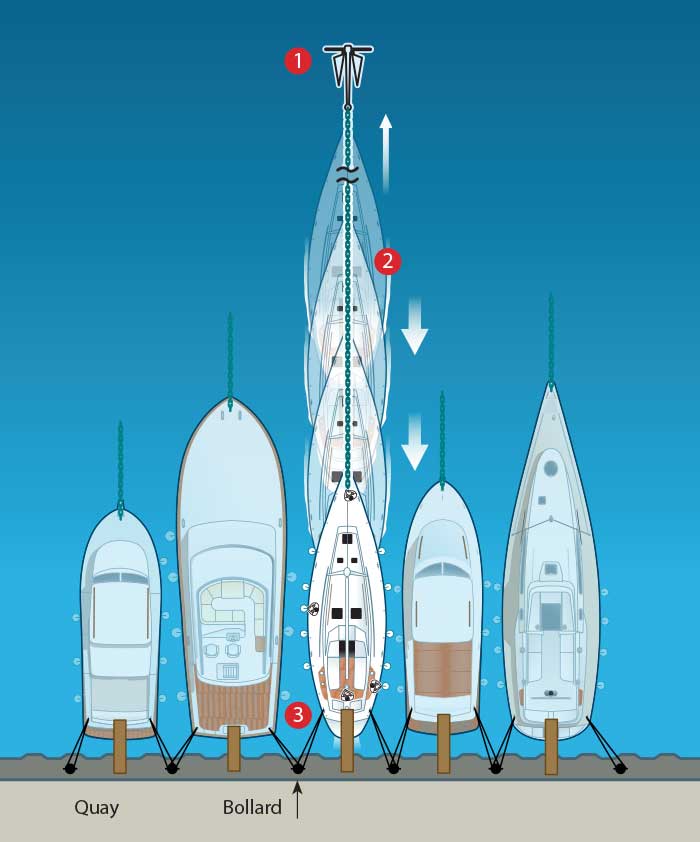

Practical Application: Line Quantity and Placement Strategies

After decades of docking boats in various conditions, I've developed systematic approaches to line placement that maximize safety while minimizing wear. Let me share the strategies that have proven most effective.

Minimum Line Requirements

Standard 6-Line Configuration

graph TD

subgraph Boat

B1[Bow Port]

B2[Bow Starboard]

M1[Midship Port Spring]

M2[Midship Starboard Spring]

S1[Stern Port]

S2[Stern Starboard]

end

subgraph Dock

D1[Forward Cleat]

D2[Aft Cleat]

D3[Spring Point]

end

B1 --> D1

B2 --> D1

M1 --> D3

M2 --> D3

S1 --> D2

S2 --> D2

My Golden Rule:

Never rely on fewer than 4 lines in any permanent mooring situation. The redundancy has saved my boat more than once during unexpected weather changes.

Professional Mooring Techniques

Crossing Spring Lines

Run bow spring to aft cleat, stern spring to forward cleat

- Creates X-pattern for maximum stability

- Reduces surge by 40-50%

- Essential in areas with wake or current

Breast Lines in Tight Quarters

Short lines perpendicular to dock

- Keeps boat parallel to dock

- Prevents contact in narrow slips

- Must allow for tidal movement

I've found that creating boat-specific placement diagrams with PageOn.ai helps new boat owners visualize exactly how to secure their vessels properly, reducing the learning curve significantly.

Maintenance, Inspection, and Replacement Guidelines

Proper maintenance can double or triple the lifespan of your dock lines. I've developed inspection protocols that have helped me catch potential failures before they become disasters.

Regular Inspection Protocols

Monthly Inspection Checklist

Immediate Replacement Indicators:

- Any cut deeper than 10% of diameter

- Significant stiffness or brittleness

- More than 25% strength loss (professional testing)

- Any damage to core (in braided lines)

Extending Dock Line Lifespan

Maintenance Timeline

The Washing Machine Trick:

Place stiff lines in a pillowcase and wash with fabric softener on gentle cycle. This removes salt crystals and restores flexibility. I do this quarterly for all my lines.

Building visual maintenance schedules through PageOn.ai's Deep Search integration has helped me create personalized care plans that extend line life while ensuring safety margins are maintained.

Advanced Considerations for Specific Vessel Types

Not all boats are created equal when it comes to dock line requirements. I've learned that vessel-specific characteristics can dramatically impact the forces on your mooring system.

High-Windage Vessels

Boats with tall cabins, flybridge, or extensive canvas present unique challenges. I've seen a 40-foot trawler exert more force on its lines than a 50-foot express cruiser in the same conditions.

Low Profile

Standard Sizing

Express cruisers, runabouts

Moderate Windage

+1 Size Recommended

Cabin cruisers, sailboats

High Windage

+2 Sizes Critical

Trawlers, houseboats

Heavy Displacement and Commercial Applications

When displacement becomes the dominant factor, traditional sizing charts need adjustment. Here's my approach for heavy vessels:

Displacement-Based Sizing Formula

For vessels over 20,000 lbs displacement:

Where Length Factor = 0.375 for boats under 30ft, 0.5 for 30-45ft, etc.

I've discovered that using PageOn.ai's customization features to create vessel-specific sizing charts helps commercial operators and yacht owners quickly determine their exact requirements without complex calculations.

Building Your Personal Dock Line Management System

After years of helping boaters secure their vessels safely, I've learned that successful dock line management isn't just about following charts—it's about understanding your specific boat, environment, and usage patterns.

Create Your Custom Chart

Document your boat's specific requirements including displacement, windage, and typical mooring conditions.

Develop a Schedule

Establish inspection, rotation, and replacement intervals based on your usage and environment.

Emergency Preparedness

Build a storm mooring plan with pre-positioned extra lines and chafe protection.

Visual Documentation

Create visual guides for crew and guests showing proper line placement and tensioning.

The transformation I've seen when boaters move from guesswork to systematic dock line management is remarkable. Suddenly, what was a source of anxiety becomes a confident, routine operation.

Remember: Your dock lines are your boat's lifeline to safety. Invest in quality, maintain them properly, and never compromise on sizing. The peace of mind is worth far more than any cost savings.

Transform Your Visual Expressions with PageOn.ai

Turn complex marine data and safety specifications into clear, actionable visual guides that protect your investment and ensure peace of mind on the water.

Start Creating with PageOn.ai TodayYou Might Also Like

Mastering Custom Image Creation with Gemini AI in Google Slides | Visual Revolution

Learn how to create stunning custom images with Gemini AI in Google Slides. Step-by-step guide to transform your presentations with AI-generated visuals for maximum impact.

Mastering Content Rewriting: How Gemini's Smart Editing Transforms Your Workflow

Discover how to streamline content rewriting with Gemini's smart editing capabilities. Learn effective prompts, advanced techniques, and workflow optimization for maximum impact.

Mastering Your First AI-Powered PowerPoint Automation Workflow | Complete Guide

Learn how to set up your first PowerPoint automation workflow with AI tools. Step-by-step guide covering Power Automate, Microsoft Copilot, and advanced techniques for efficient presentations.

Essential MCP Tools for Automated Slide Creation and Design | PageOn.ai

Discover essential Model Context Protocol (MCP) tools for automated slide creation and design. Learn how to transform presentation workflows with AI-powered automation.